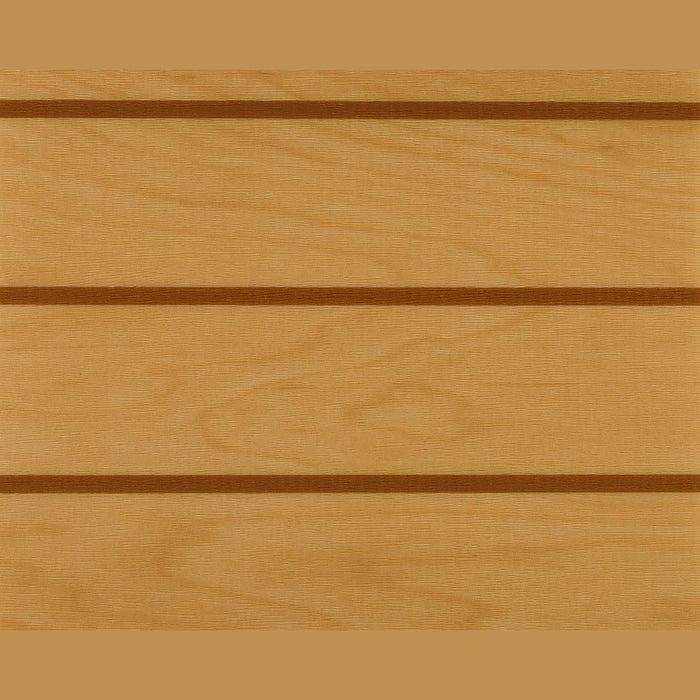

Lonseal Lonmarine Wood Flooring

Artfully blending the distinguished look of strip-wood decks with the superior durability of Lonseal's resilient sheets, Lonwood marine flooring brings elegant wood-grain aesthetics to your ship or vehicle interiors with greater economy and simpler upkeep.

Specifications:

- Roll Width: 6 Feet (1830 mm)

- Roll Length: 60 Feet(18 m)

- Thickness: 80 mil (2.0 mm)

Features:

- Lonwood Marine Flooring is a resilient sheet vinyl flooring solution with an interesting texture that mirrors the look of natural wood grains

- Excellent for small and large marine vessel interiors where design parameters call for a high- performance, sophisticated flooring solution

- Excellent for interior, retail, commercial, or institutional use where design parameters call for a high performance, sophisticated flooring solution

-

Suitable Substrates Subject to Lonseal's Technical Manual for Interior Products:

- Concrete (All grade levels), underlayment grade plywood, metal, and terrazzo

-

Composition:

- Constructed in multiple layers and embossed with distinctive wood grains

- Lonwood Marine Flooring is composed of multiple layers of polyvinyl chloride resin, plasticizers, fillers, and pigments

- With an embossed wood-grain texture, the co-calendared wear layer is formulated to provide maximum resistance to foot traffic in most commercial and healthcare applications

- The middle layer provides dimensional stability, sound-absorbing properties, and resiliency under foot

- The backing layer provides strength and stability of the flooring and enhances the bonding strength of the adhesive

-

Green Features:

- Over 35% pre consumer recycled content

- Toward LEED (MR 4.1, MR 4.2)

- EQ 4.1: Low VOC Adhesive

-

Standard Sizes

- Nominal thickness: .058" (1.9 mm)

- Wear layer thickness: .011" (0.3 m

Technical Data:

-

Applicable Standards

- Type: I

- Grade: I

- Backing: Class B

- Conforms with ASTM F 1303

-

Coefficient of Friction (COF):

- (ASTM C 1028) Surpasses ADA

guidelines

- (ASTM C 1028) Surpasses ADA

-

Critical Radiant Flux:

- (ASTM E 648) Class 1 per NFPA Life

Safety Code 101

- (ASTM E 648) Class 1 per NFPA Life

-

Smoke Density:

- (ASTM E 662/NFPA 258)

-

Abrasion Resistance:

- (ASTM D 3884)

Net Weight Loss after 1000 revolutions: 0.5%

- (ASTM D 3884)

-

Static Load Limit:

- (ASTM F 970) Residual compression - after exposure to a load of 500 lbs./24 hr.- .005"

-

Flexibility:

- (ASTM F 137) Passes

-

Chemical Resistance:

-

No Change:

- 5% Ammonia

- 5% Acetic Acid

- 70% Isopropyl Alcohol

- 5% Sodium Hydroxide

- 5% Hydrochloric Acid

- Mineral Oil

- Gasoline

- Bleach

- Sulfuric Acid

- Kerosene

- Olive Oil

-

Surface Attack and Slight Change:

- 5% Phenol

-

No Change:

Storage: Store all surfacing materials in a clean, dry environment with unopened rolls standing on end. Please refer to Lonseal's Technical Manual for Interior Products for detailed information.

Adhesives and Seam Treatment: Seams are chemical and heat weldable

- No. 300: Epoxy For extreme service requirements

- No. 400: Contact Adhesive for Vertical Installations

- Lonseal Double Face Tape Under seams

- Lonsealer: Chemical seam sealer

Maintenance:

- This unique wear layer provides low maintenance that requires only dust and wet mopping

- For interim maintenance, we recommend use of Lonseal"s maintenance products: Lonbuff and Loncare

Sold by the linear foot

SHIPPING

Thank you for considering our Lonseal Lonmarine flooring for your project! Shipping for this size of item is typically done via freight shipping, which may incur additional fees. To ensure that you get the best possible rate for shipping, we will contact you prior to shipment with the final shipping cost. This way, you won't have to worry about paying more than necessary for shipping.